English

English

English

English

Español

Español

Português

Português

русский

русский

français

français

日本語

日本語

Deutsch

Deutsch

Tiếng Việt

Tiếng Việt

Italiano

Italiano

Nederlands

Nederlands

ไทย

ไทย

Polski

Polski

한국어

한국어

Svenska

Svenska

magyar

magyar

Malay

Malay

বাংলা

বাংলা

Dansk

Dansk

Suomi

Suomi

हिन्दी

हिन्दी

Pilipino

Pilipino

Türk

Türk

Gaeilge

Gaeilge

عربى

عربى

Indonesia

Indonesia

norsk

norsk

اردو

اردو

čeština

čeština

Ελληνικά

Ελληνικά

Українська

Українська

Javanese

Javanese

فارسی

فارسی

தமிழ்

தமிழ்

తెలుగు

తెలుగు

नेपाली

नेपाली

Burmese

Burmese

български

български

ລາວ

ລາວ

Latine

Latine

Қазақ

Қазақ

Euskal

Euskal

Azərbaycan

Azərbaycan

slovenský

slovenský

Македонски

Македонски

Lietuvos

Lietuvos

Eesti Keel

Eesti Keel

Română

Română

Slovenski

Slovenski

मराठी

मराठी

Српски

Српски

Esperanto

Esperanto

Afrikaans

Afrikaans

Català

Català

עִברִית

עִברִית

Cymraeg

Cymraeg

Galego

Galego

Latvietis

Latvietis

icelandic

icelandic

יידיש

יידיש

Беларус

Беларус

Hrvatski

Hrvatski

Kreyòl ayisyen

Kreyòl ayisyen

Shqiptar

Shqiptar

Malti

Malti

lugha ya Kiswahili

lugha ya Kiswahili

አማርኛ

አማርኛ

Bosanski

Bosanski

Frysk

Frysk

ជនជាតិខ្មែរ

ជនជាតិខ្មែរ

ქართული

ქართული

ગુજરાતી

ગુજરાતી

Hausa

Hausa

Кыргыз тили

Кыргыз тили

ಕನ್ನಡ

ಕನ್ನಡ

Corsa

Corsa

Kurdî

Kurdî

മലയാളം

മലയാളം

Maori

Maori

Монгол хэл

Монгол хэл

Hmong

Hmong

IsiXhosa

IsiXhosa

Zulu

Zulu

Punjabi

Punjabi

پښتو

پښتو

Chichewa

Chichewa

Samoa

Samoa

Sesotho

Sesotho

සිංහල

සිංහල

Gàidhlig

Gàidhlig

Cebuano

Cebuano

Somali

Somali

Точик

Точик

O'zbek

O'zbek

Hawaiian

Hawaiian

سنڌي

سنڌي

Shinra

Shinra

հայերեն

հայերեն

Igbo

Igbo

Sundanese

Sundanese

Lëtzebuergesch

Lëtzebuergesch

Malagasy

Malagasy

Yoruba

Yoruba

Javanese

Javanese

Banbala

Banbala

Pokjoper

Pokjoper

Divih

Divih

Philippine

Philippine

Gwadani

Gwadani

Elokano

Elokano

Zhejiang Qingqichen Electric Heating Co., Ltd.

News

-

Electric heating tape grid heating mat

Electric heating tape grid heating mat is a new type of heating product. It combines the advantages of electric heating tape and grid heating mat, providing people with an efficient, environmentally friendly and comfortable heating method.

-

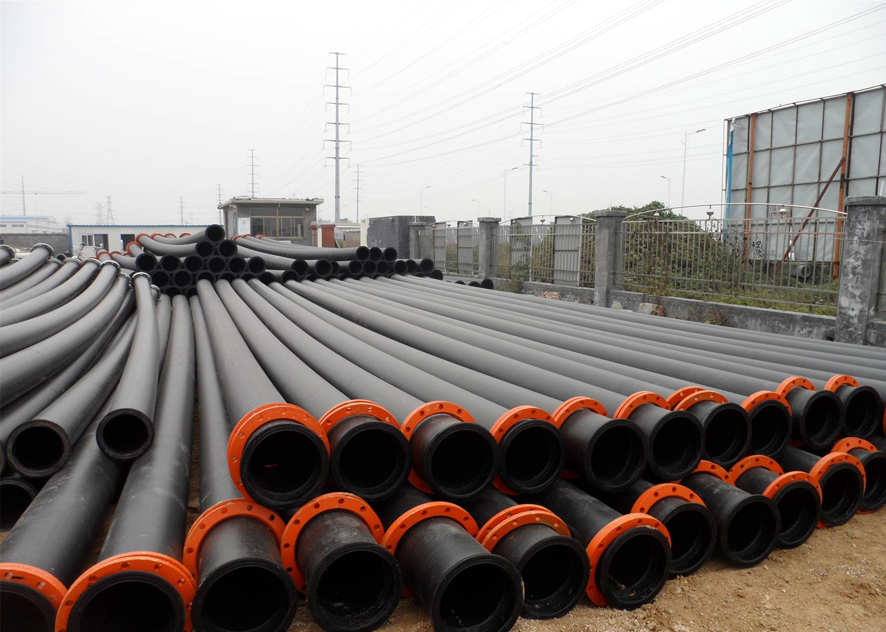

Features of heating tape for plastic pipes

Heating tape is an electric heating device that can be used for insulation and anti-freezing of various pipes. Its working principle is to supplement the heat loss by generating heat from the electric heating wire to maintain the temperature of the material in the pipeline and ensure the normal operation of the pipeline. Plastic pipes are one of the common applications for heating tapes. The following introduces the characteristics of heating tape used in plastic pipes.

-

Electric heating tape is used to melt snow at airports

Airport snowmelt is key to maintaining normal airport operations in winter. Under extreme weather conditions, snow-covered runways and aprons can pose huge safety risks for aircraft taking off and landing, seriously endangering the safety of passengers, crew and airport staff. Traditional methods include manual removal and heating equipment, but these methods are inefficient and time-consuming. With the development of science and technology, electric heating tape, as an efficient and energy-saving snow melting equipment, has been widely used in the field of airport snow melting. This article will introduce the principles, advantages and application of electric heating tapes in airport snow melting.

-

Electric heating: a solution for efficient insulation of catalyst pipelines

In the chemical and petroleum industries, the insulation of catalyst pipes is crucial. Poor insulation will cause the temperature of the fluid in the pipeline to drop, affecting the activity of the catalyst and reaction efficiency. In order to solve this problem, electric heat tracing, as an effective heat preservation method, has gradually been widely used. This article will introduce in detail the effects and advantages of electric heating for catalyst pipeline insulation.

-

Precautions for waterproofing of electric heating system

With the continuous development and advancement of science and technology, electric heating systems have been widely used in many fields. However, during use, due to the particularity of its working environment, such as high temperature, high pressure, corrosion, etc., as well as the influence of the outdoor environment, it is easy to cause system aging, damage, and even safety accidents such as leakage. The following is a brief description of the precautions for waterproofing the electric heating system.

-

Causes of electric heating failure

As an effective pipe insulation and anti-freeze solution, electric heating has been widely used in many fields. However, you may encounter some problems during use, the most common of which is electric heat tracing failure. Let’s discuss the causes of electric heating failures.

-

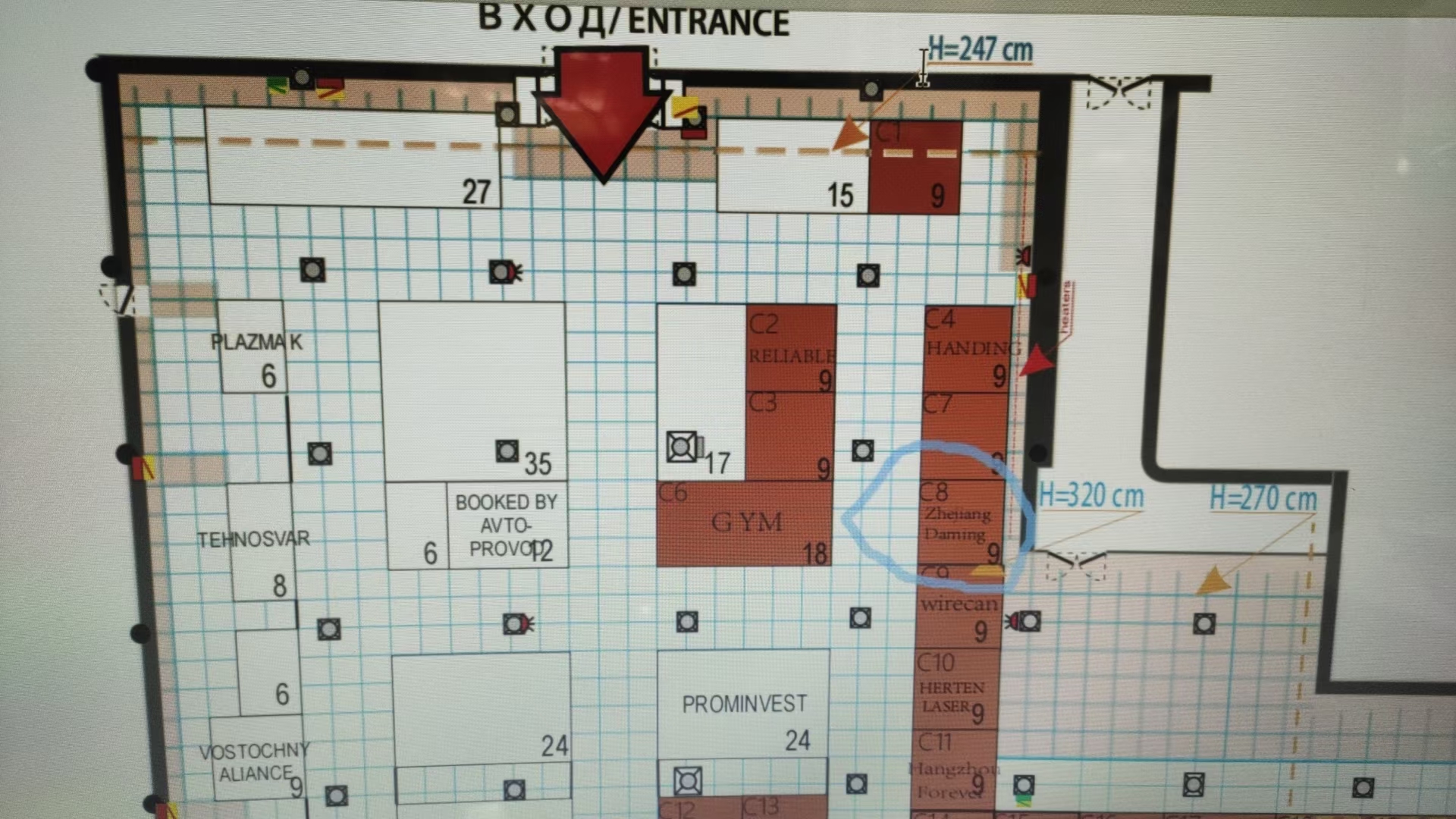

ZhejiangQingqi Dust Environmental Co., Ltd. will participate in the Wire and Cable Exhibition in Moscow, Russia

From March 19 to 21, 2024, Zhejiang Qingqi Dust Environmental Co., Ltd. will participate in the Wire and Cable Exhibition in Moscow, Russia. New and old customers are welcome to come to the exhibition to communicate and negotiate!

-

Jointly build the “One Belt and One Road” initiative to stimulate new momentum for Fuyang enterprises

Recently, the third "Belt and Road" International Cooperation Summit Forum was held in Beijing. On the occasion of the 10th anniversary of the joint construction of the "Belt and Road" initiative, Chinese and foreign guests gathered at the National Convention Center in Beijing for the ten-year appointment.

-

Issues that need attention in the design of electric heat tracing and insulation of pipelines

In the insulation design of electric heating pipelines, designers must proceed from reality and determine the heating system parameters and design indicators according to the specific process medium implementation requirements, so that the process medium will not have condensation or blockage problems during system operation.

-

Application of electric heating in antifreeze and anticondensation in chemical plants

Chemical plants are characterized by many equipment, pipes and instruments interconnected to complete normal operation. Since today's petrochemical plants are large-scale, have strong production continuity, low levels of self-control, and contain many dangerous materials such as flammable and explosive, and the equipment height varies, a fully enclosed approach cannot be adopted to solve the problems of winter frost protection and protection in severe cold areas. Anti-condensation problem. Therefore, antifreeze and anticondensation work in winter is very important.